Centrifugal casting is a unique manufacturing process used to produce cylindrical parts and components by pouring molten material into a spinning mold. The centrifugal force generated during the process distributes the molten material evenly, producing high-quality and durable products. This technique is widely used in industries such as automotive, aerospace, and metallurgy for creating pipes, bushings, and bearings. Despite its advantages, centrifugal casting has certain limitations. This article explores the advantages and disadvantages of centrifugal casting in detail.

What is Centrifugal Casting?

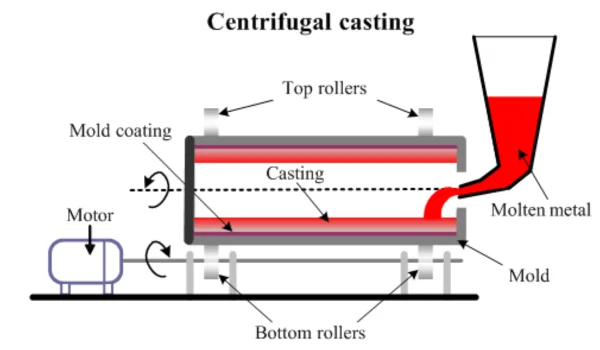

Centrifugal casting involves pouring molten metal into a rotating mold. As the mold spins at high speed, the centrifugal force pushes the material outward, creating a dense and defect-free component. The rotation ensures uniform distribution of material and eliminates impurities, making this process ideal for manufacturing hollow and cylindrical parts.

Advantages of Centrifugal Casting

- High-Quality Products

Centrifugal casting produces components with excellent mechanical properties. The process removes impurities, creating dense and defect-free products with high structural integrity. - Uniform Distribution

The centrifugal force ensures even distribution of material, resulting in uniform thickness and consistent quality throughout the component. - Cost-Effectiveness

The process is efficient and requires minimal machining, reducing material waste and production costs. Additionally, reusable molds lower manufacturing expenses. - Strength and Durability

Components made through centrifugal casting exhibit superior strength and durability due to the elimination of porosity and inclusions. - Versatility

The process is suitable for a wide range of materials, including metals, alloys, and composites. It is used to manufacture pipes, gears, bushings, and cylinders. - Large-Scale Production

Centrifugal casting is ideal for producing large quantities of identical components, ensuring consistency and cost efficiency in mass production. - Minimal Defects

The high rotational speed and rapid solidification eliminate gas pockets, shrinkage, and other common casting defects. - Flexibility in Design

The technique allows for the production of complex shapes, such as tapered or flanged components, by modifying the mold design. - Improved Corrosion Resistance

Components created using this process often have superior surface finishes, which enhance their resistance to corrosion. - Environmental Benefits

The process reduces material waste, making it more environmentally friendly compared to some traditional casting methods.

Disadvantages of Centrifugal Casting

- High Initial Costs

The setup costs for centrifugal casting are relatively high due to the need for specialized equipment and molds. - Limited to Rotational Symmetry

This process is primarily suitable for cylindrical or symmetrical components, limiting its application for non-circular shapes. - Material Restrictions

While versatile, centrifugal casting may not be suitable for certain materials, particularly those with low fluidity or high melting points. - Complex Operation

The process requires skilled operators and precise control of parameters, such as rotational speed and temperature, to ensure quality output. - Mold Wear and Tear

The high rotational speeds and thermal stresses can lead to rapid wear and tear of molds, increasing maintenance costs. - Inconsistent Internal Properties

While the outer layers are typically dense and strong, the inner layers may have slightly different properties due to the centrifugal force distribution. - Size Limitations

The size of the component is limited by the capacity of the casting equipment and the mold, restricting its use for very large-scale applications. - Surface Finish Issues

Although centrifugal casting often produces high-quality surfaces, additional machining may be required for tight tolerances or specific finishes. - Not Ideal for Small Quantities

The cost-effectiveness of centrifugal casting diminishes for small production runs due to the high initial setup and equipment costs. - Safety Concerns

The high speeds and molten material involved in the process pose safety risks, requiring strict adherence to safety protocols.

Comparison Table: Advantages vs. Disadvantages

| Advantages | Disadvantages |

|---|---|

| Produces high-quality, defect-free components | High initial setup costs |

| Uniform material distribution | Limited to rotational symmetry |

| Cost-effective with minimal waste | Material restrictions for certain alloys |

| Superior strength and durability | Requires skilled operation and precise control |

| Suitable for mass production | Mold wear and tear increases maintenance |

| Eliminates porosity and inclusions | Size limitations due to equipment capacity |

| Supports complex designs | Additional machining for specific finishes |

| Improved corrosion resistance | Less economical for small production runs |

| Environmentally friendly process | Safety risks due to high speeds and molten metal |

Applications of Centrifugal Casting

- Automotive Industry: Manufacturing engine components, bushings, and gears.

- Aerospace Industry: Producing high-strength and lightweight cylinders and tubes.

- Oil and Gas Sector: Creating corrosion-resistant pipes for transporting fluids.

- Industrial Equipment: Bearings, rollers, and wear-resistant parts.

- Power Generation: Components for turbines, such as rings and casings.

Best Practices in Centrifugal Casting

- Quality Mold Design: Use high-quality molds to reduce wear and ensure consistent output.

- Parameter Control: Maintain precise control of temperature and rotational speed for optimal results.

- Regular Maintenance: Inspect and maintain equipment to prevent downtime and ensure safety.

- Material Selection: Choose appropriate materials based on the application and process requirements.

- Skilled Workforce: Train operators to handle the complexities of the process effectively.

Conclusion

Centrifugal casting is a powerful manufacturing technique that offers numerous advantages, including superior product quality, cost-efficiency, and design versatility. Its ability to produce dense, durable, and defect-free components makes it a preferred choice in various industries. However, the process also has its limitations, such as high initial costs, material restrictions, and operational complexity.

By carefully weighing the advantages and disadvantages, businesses can determine whether centrifugal casting aligns with their specific needs. When applied correctly, this process can deliver high-performance components that meet demanding industrial requirements, making it a valuable tool in modern manufacturing.

Hello, I’m Kapil Kumar, a seasoned SEO expert and blogger at WinnersList.in. My mission is to spotlight exceptional individuals and organizations across various domains. Through curated lists, profiles, and inspiring stories, I aim to celebrate outstanding achievements and inspire the next generation of champions. Join me in this journey.