A hammer mill is an essential machine in industries such as agriculture, pharmaceuticals, food processing, and mining. It is used to crush, grind, and pulverize materials into smaller, more manageable sizes. The simplicity and efficiency of the hammer mill make it a popular choice in various applications, but it also has some drawbacks. This article discusses the advantages and disadvantages of hammer mills in detail.

What is a Hammer Mill?

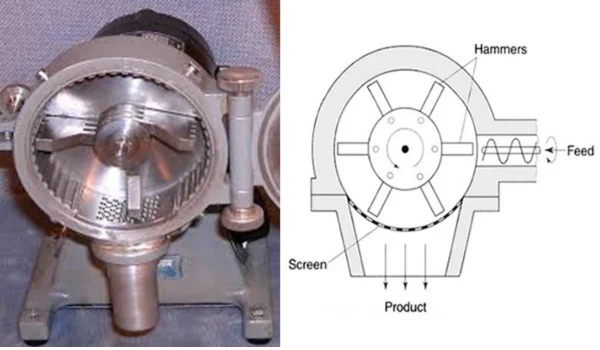

A hammer mill is a mechanical device consisting of a rotating shaft with hammers attached. When the machine operates, the hammers swing to crush or pulverize materials fed into the mill. The size of the output material depends on the type of screen or grate used in the mill. Hammer mills are versatile and can handle a variety of materials, including grains, minerals, and waste products.

Advantages of Hammer Mills

- Versatility

Hammer mills can process a wide range of materials, including soft, medium-hard, and fibrous substances. This versatility makes them suitable for industries such as agriculture, mining, and pharmaceuticals. - Simple Design and Operation

The design of a hammer mill is relatively simple, with fewer moving parts, making it easy to operate and maintain. Operators require minimal training to use the machine effectively. - High Efficiency

Hammer mills operate at high speeds, allowing them to process materials quickly and efficiently. This feature is particularly beneficial in high-demand production environments. - Adjustable Output Size

By changing the screen or grate size, users can control the output particle size, making the hammer mill adaptable to different applications. - Cost-Effective

Hammer mills are generally more affordable than other milling equipment, making them an economical choice for small and medium-sized businesses. - Durable and Robust

The robust construction of hammer mills ensures long-lasting performance, even in demanding conditions. This durability reduces the frequency of repairs and downtime. - Reduction of Waste

Hammer mills are effective at recycling and processing waste materials, such as agricultural residues and industrial by-products, into valuable secondary products. - Energy Efficiency

Compared to some other milling equipment, hammer mills are relatively energy-efficient, reducing operational costs over time.

Disadvantages of Hammer Mills

- Noise and Vibration

Hammer mills produce significant noise and vibration during operation, which can be disruptive in some environments and may require additional soundproofing measures. - Limited to Dry Materials

Hammer mills are most effective with dry materials. Moist or sticky substances can clog the machine, reducing efficiency and requiring frequent cleaning. - Particle Uniformity Issues

The output particle size from a hammer mill may not be as uniform as that from other grinding methods, such as roller mills, which can be an issue for specific applications. - Wear and Tear

The hammers and screens in a hammer mill experience wear over time, especially when processing abrasive materials. Regular maintenance and replacement of parts are necessary to maintain efficiency. - Dust Generation

Hammer mills can produce a significant amount of dust during operation, posing health and safety risks for operators and potentially affecting air quality. - Power Requirements

Despite being energy-efficient, hammer mills still require a consistent power supply to operate, which may be challenging in remote areas with limited access to electricity. - Not Suitable for Very Hard Materials

While hammer mills can handle many materials, extremely hard substances like certain types of rocks or metals may damage the hammers or other components. - Risk of Over-Grinding

If not monitored, hammer mills can over-grind materials, leading to excessive fines that may not be suitable for the intended application.

Comparison Table: Advantages vs. Disadvantages

| Advantages | Disadvantages |

|---|---|

| Versatile, processes a wide range of materials | Generates noise and vibration |

| Simple design and easy to operate | Limited to dry materials |

| High efficiency and fast processing | Inconsistent particle size |

| Adjustable output size | Wear and tear on parts |

| Cost-effective for small and medium businesses | Dust generation can be a health risk |

| Durable and robust construction | Requires consistent power supply |

| Reduces waste by recycling materials | Not suitable for very hard materials |

| Energy-efficient operation | Risk of over-grinding materials |

Applications of Hammer Mills

- Agriculture: Grinding grains for animal feed, processing agricultural residues.

- Food Processing: Pulverizing spices, herbs, and other food items.

- Pharmaceuticals: Milling active ingredients into fine powders.

- Mining: Crushing and grinding ores and minerals.

- Waste Management: Recycling biomass and industrial waste into usable products.

How to Overcome Disadvantages

- Noise and Vibration: Install soundproof enclosures and vibration dampers.

- Dust Control: Use dust collection systems to maintain air quality and ensure operator safety.

- Maintenance: Regularly inspect and replace worn parts to avoid downtime and maintain efficiency.

- Moisture Management: Pre-dry materials before feeding them into the mill to avoid clogging.

Conclusion

Hammer mills are versatile and efficient tools for material processing, offering numerous advantages such as cost-effectiveness, simplicity, and high throughput. However, their disadvantages, including noise, wear, and limitations with certain materials, must be carefully managed to maximize their benefits.

By understanding the advantages and disadvantages of hammer mills, businesses can make informed decisions about whether this equipment suits their specific needs. With proper maintenance and operational practices, hammer mills can be a valuable asset across various industries.

Hello, I’m Kapil Kumar, a seasoned SEO expert and blogger at WinnersList.in. My mission is to spotlight exceptional individuals and organizations across various domains. Through curated lists, profiles, and inspiring stories, I aim to celebrate outstanding achievements and inspire the next generation of champions. Join me in this journey.